Select menu

Storage for Packaged Ice and Other Food Applications

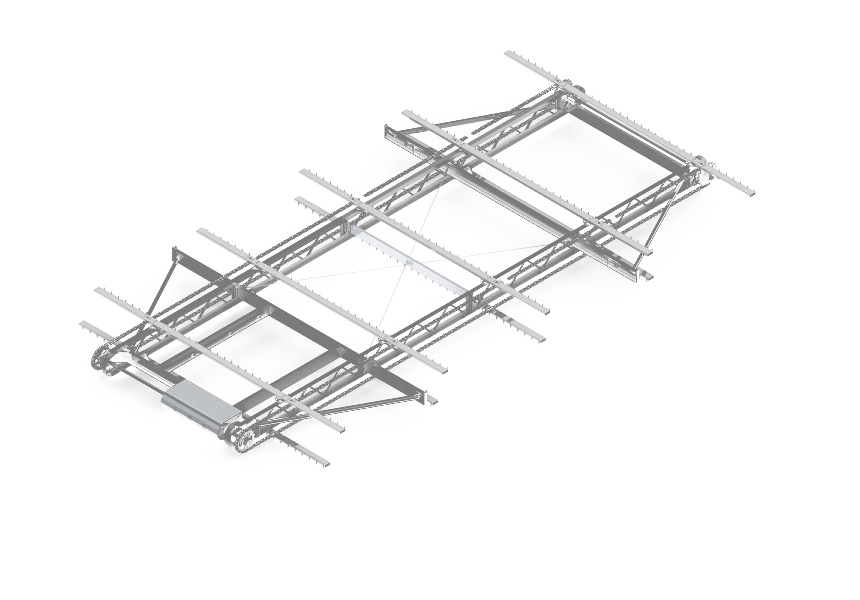

North Star combines its ice storage systems with ice makers and delivery systems in a custom design to meet your specific ice production, storage and delivery requirements. At the heart of the system is North Star’s patented ice rake. The rake levels ice in the storage bin to maximize storage space and automatically discharges it when it is needed. North Star ice rakes have long been proven the most efficient and dependable way to handle ice.

North Star offers five types of ice storage systems with storage capacities ranging from 12 tons to 250 tons (11 to 227MT) per unit. Units can be combined to increase storage capacity.

Equipment Features

Standard Features

To explore the various features and benefits of our Stainless Steel Modular Ice Storage Systems, please view this chart.

- Galvanized tubular steel wall frames with galvanized steel bin liners

- Electric operated rake assembly with soft starting fluid drive coupling and low speed overload detection

- Electric operated vari-speed hoist assembly with galvanized drip pan, and electronic controller with "bin empty" and "bin full" detection

- Electric operated bin door assembly with viewing panels and plastic liner. Linear actuator-type bin door operator on SMR and LMR, automatic winch-type bin door operator on JMR, HMR, GMR, and FMR

- Manual control station for rake, hoist and bin door

- Electrical control panel with programmable logic controller with motor starters for rake, hoist, bin door and discharge screw, door mounted operator interface panel, consolidated power supply wiring with main disconnect, circuit breakers and control power transformer

- Stainless steel drive shaft and guard cover

Stainless Steel Options

- Rake flights, chain, sprockets

- Wear and thrust plates

- Bin liners

- Truss covers

- 100% stainless steel rakes available

Control Panel Options

- Motor starters for additional conveying equipment

- Enhanced operator interface with status and fault message display

- Internet communication

System Components

North Star packaged ice systems are available in two options – the MR-Plus and the MR-Elite. The design of the MR-Plus ensures that ice comes into contact with only stainless steel or food-grade plastic components. The MR-Elite is for applications that require a completely stainless steel rake assembly, with all components inside the ice bin made of stainless steel or food grade plastic.

-

MR-Plus System

Ice Rake

Stainless steel truss covers, truss shoes and rake flights

Rake Chain

Stainless steel or food-grade plastic*

Drive Assembly

Stainless steel cover & drive shaft

Drive and Idle Sprockets

Stainless steel or food grade plastic*

Bin Wall Frames

Reinforced bin wall frames with bin liners, and hinged side access doors with viewing panels

Stainless steel bin panels, and wear and thrust plates

Delivery Systems

Stainless steel screw conveyors -- 10 to 30 U.S. tons (9 to 27 MT) per hour delivery rate.

-

MR-Elite System

Ice Rake

Complete rake assembly is stainless steel

Rake Chain

Stainless steel or food-grade plastic*

Drive Assembly

Stainless steel cover & drive shaft

Drive and Idle Sprockets

Stainless steel or food grade plastic*

Bin Wall Frames

Reinforced bin wall frames with bin liners, and hinged side access doors with viewing panels

Stainless steel bin panels, wear and thrust plates, bottom tie bars, and bottom flat bar strips

Delivery Systems

Stainless steel screw conveyors -- 10 to 30 U.S. tons (9 to 27 MT) per hour delivery rate.

*Varies depending on rake model selected

Helpful Technical Information

Use the Capacity Calculator below to size the correct ice maker for your project. Download helpful brochures, specification sheets, and other technical data in our Resources Library.